Contact

You can reach us from the contact information below.

Telephone +90 (262) 641 95 25

Mail info@silvanrolls.com

SD-P-48

Description

As a result of our research and studies, we have developed solutions for the problems like sharp hardness falls, minimization of heat cracks due to thermal shocks and keeping the roll life decline at minimum levels in cases where welding is unavoidable.

Our high alloyed ‘Mo’ rolls subjected to a special heat treatment process enable constant hardness from surface to the core of the rolls. This superiority provides strength against heat cracks and breakages.

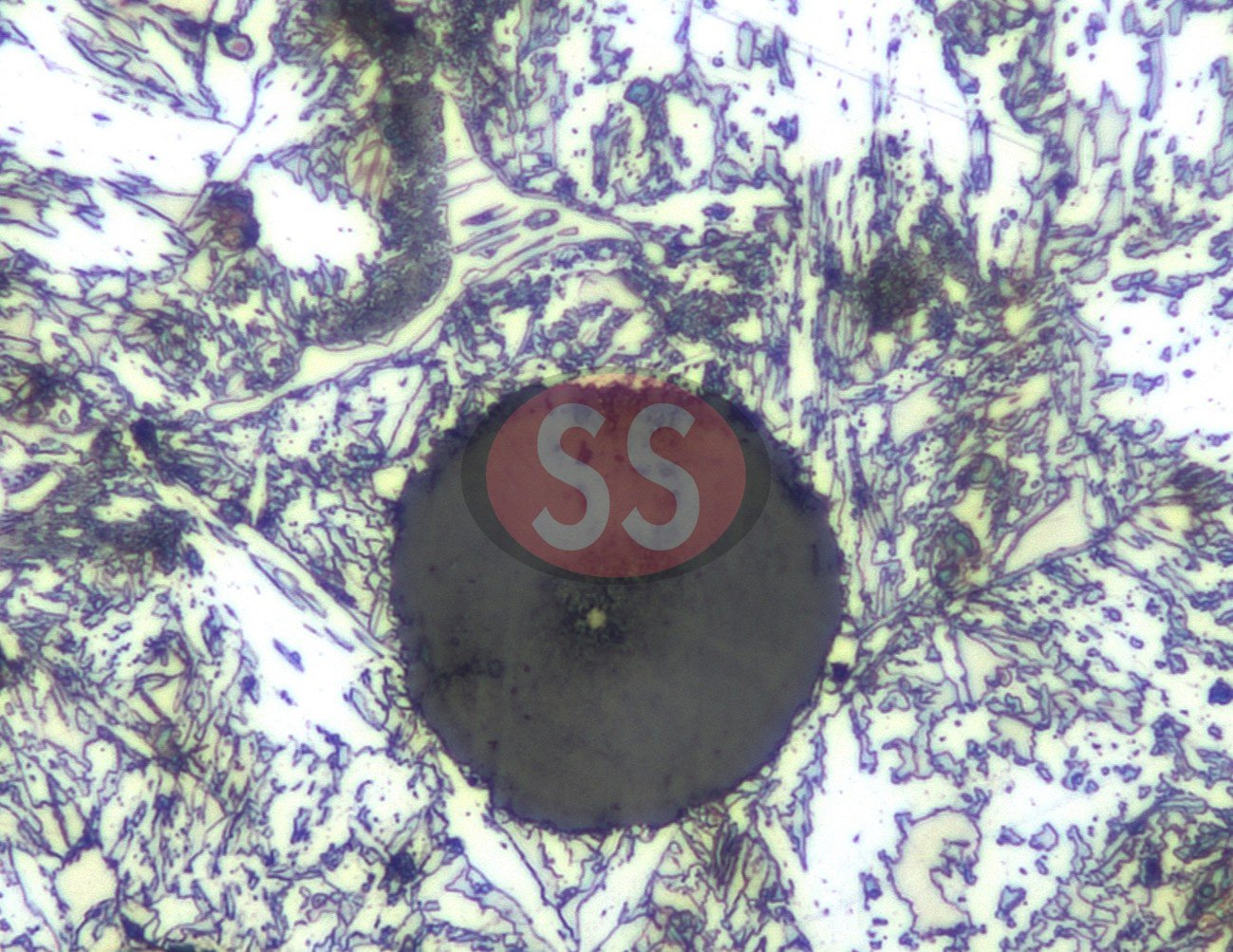

Nodular graphite cast iron rolls are produced from alloy cast iron spheroidal graphite material that has high resistance to wear.

Softer grades of these rolls are more resistant to heat cracks and harder ones resistant to wear.

- Cr, Ni, Mo alloyed spheroidal cast iron

- Pearlite + Carbide + Spherolite

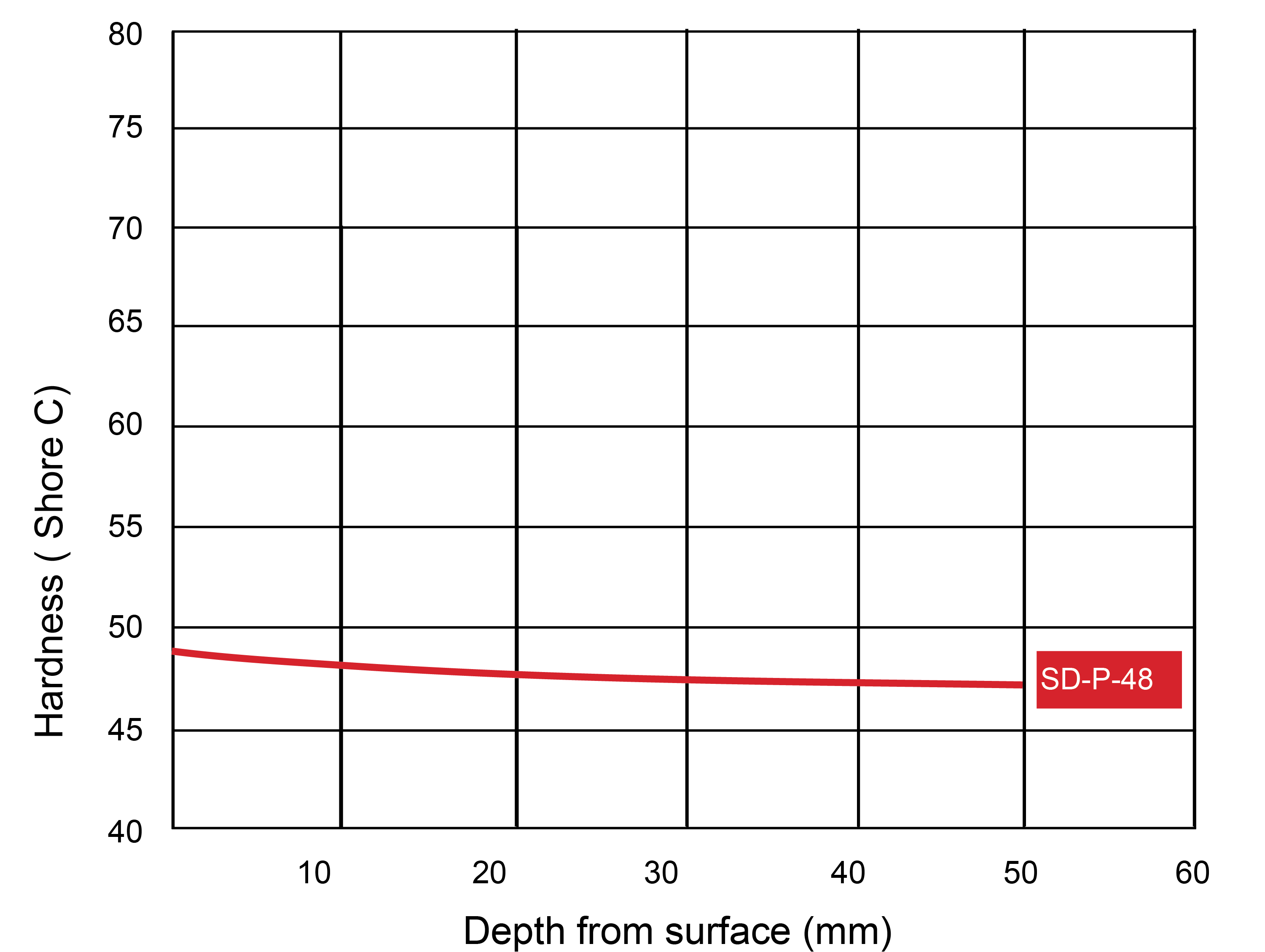

- Constant hardness curve

- Tensile strangth: 575 – 750 N/mm2, Bending strength: 950 – 1300 N/mm2

- On large section mills, roughing stands

- Resistance to overloads

- Resistance to impact loads

- Resistance to thermal shocks

Hardness Profile

Microstructure

Chemical Analysis & Hardness

| HARDNESS (SHORE C) |

CHEMICAL ANALYSIS | |||||

| C% | Si% | Mn% | Cr% | Ni% | Mo% | |

| 46-50 | 3.0 - 3.5 | 1.2 - 1.8 | 0.3 - 0.8 | 0.0 - 0.2 | 2.0 - 3.0 | 0.6 - 1.0 |

Mechanical Properties

| MECHANICAL PROPERTIES | |||

| Tensile Strength (N/mm2) |

Bending Strength (N/mm2) |

Microstructure | |

| 575-750 | 950 -1300 | Carbides + Spherolite in pearlitic matrix | |